Background to Wadokei Manufacture

Every part in the movement of a Wadokei was made by hand, and that is the reason the makers were not called “Tokei-ya” (clock makers) but “Tokei-shi” (Clock-smiths).

A Japanese clocksmith made all parts of a timepiece and specialization among craftsmen regarding the production of single parts of timepieces did not develop in old Japan in the way it did in Europe. It is generally believed that it took more than one year for a craftsman to produce a clock and it is said that some of the famous makers produced less than ten clocks during their lifetime.

It is recorded in several places that the Machine Lathe as known in the Western World did not appear in Japan until 1830.

As dials, ornamental pillars, and similar parts could not be made solely by hand, it is evident that an instrument such as “Clockmakers’ Turns” must have been used. Further, there is evidence that rotating worktables were used in pottery, therefore some means of rotational tools would have existed.

In 1851, Hisashige Tanaka (of Mannen Dokei fame) advertised that for his jimei-sho: “The body of the clock is made by lathe (senban), a device that I invented.” Hisashige was reputed at that time to have been the inventor of the lathe, as well as inventing a lathe to turn an ellipse.

In the 1830’s there were clocksmiths in different cities who produced clocks of novel shapes and of beautiful finishes. These hand-made clocks was an indication of the art and skill which the Japanese craftsman had attained. Designs of various wadokei were exhibited in shops, and they were made in Nagasaki, Kyoto, Osaka, Yedo, Sendai, amongst other places. How far back the work of the Wadokei-smith became a recognized craft is not apparent.

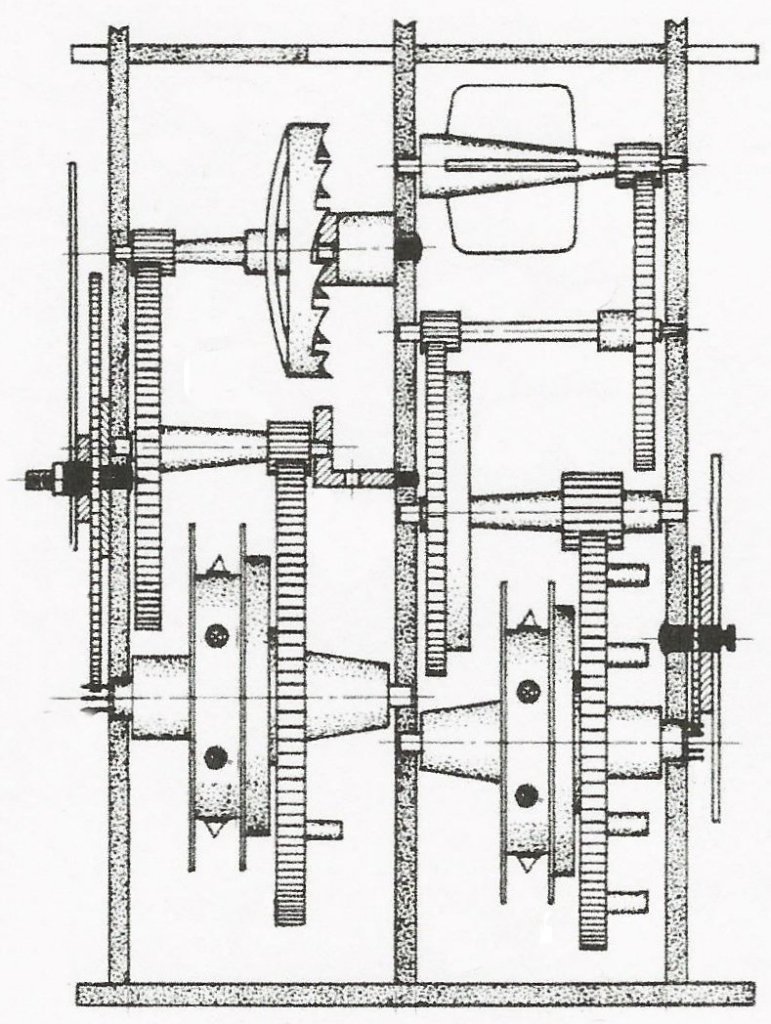

Typical Lantern Clock Construction

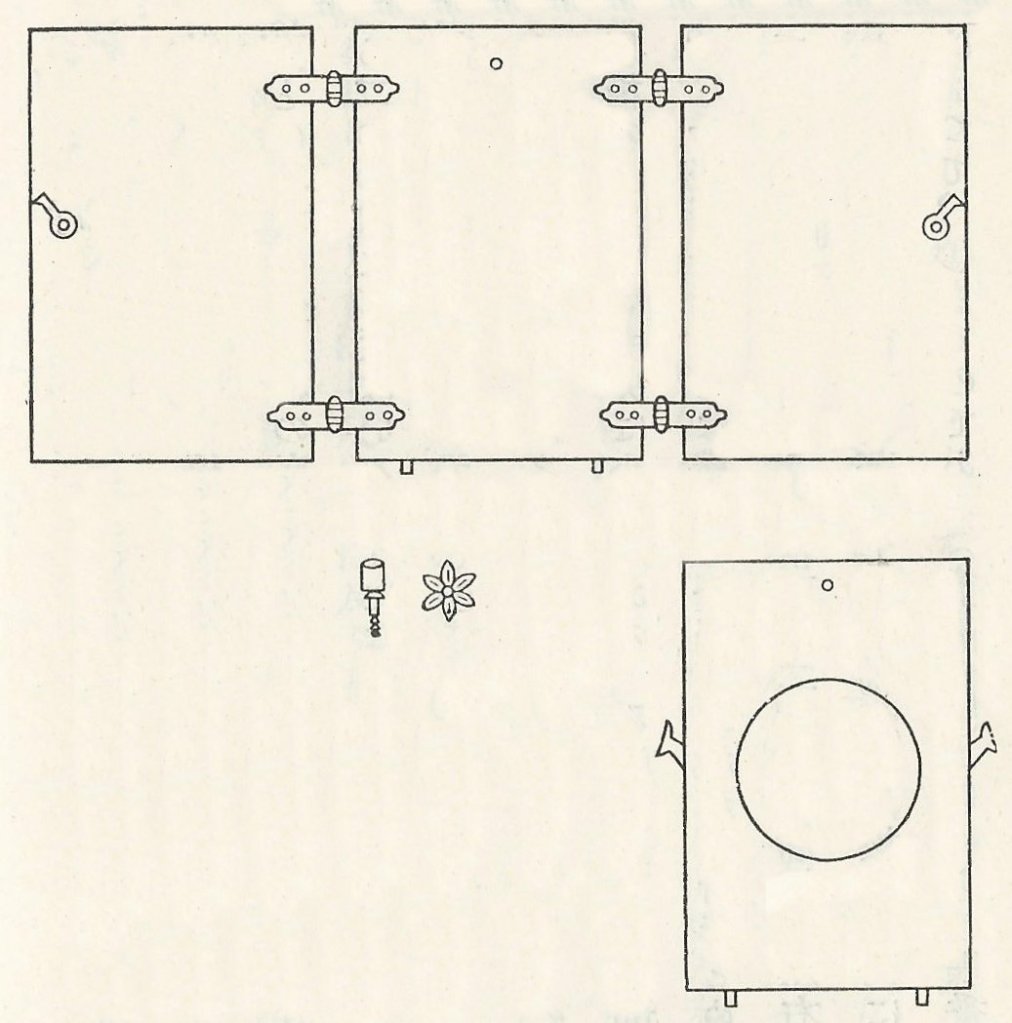

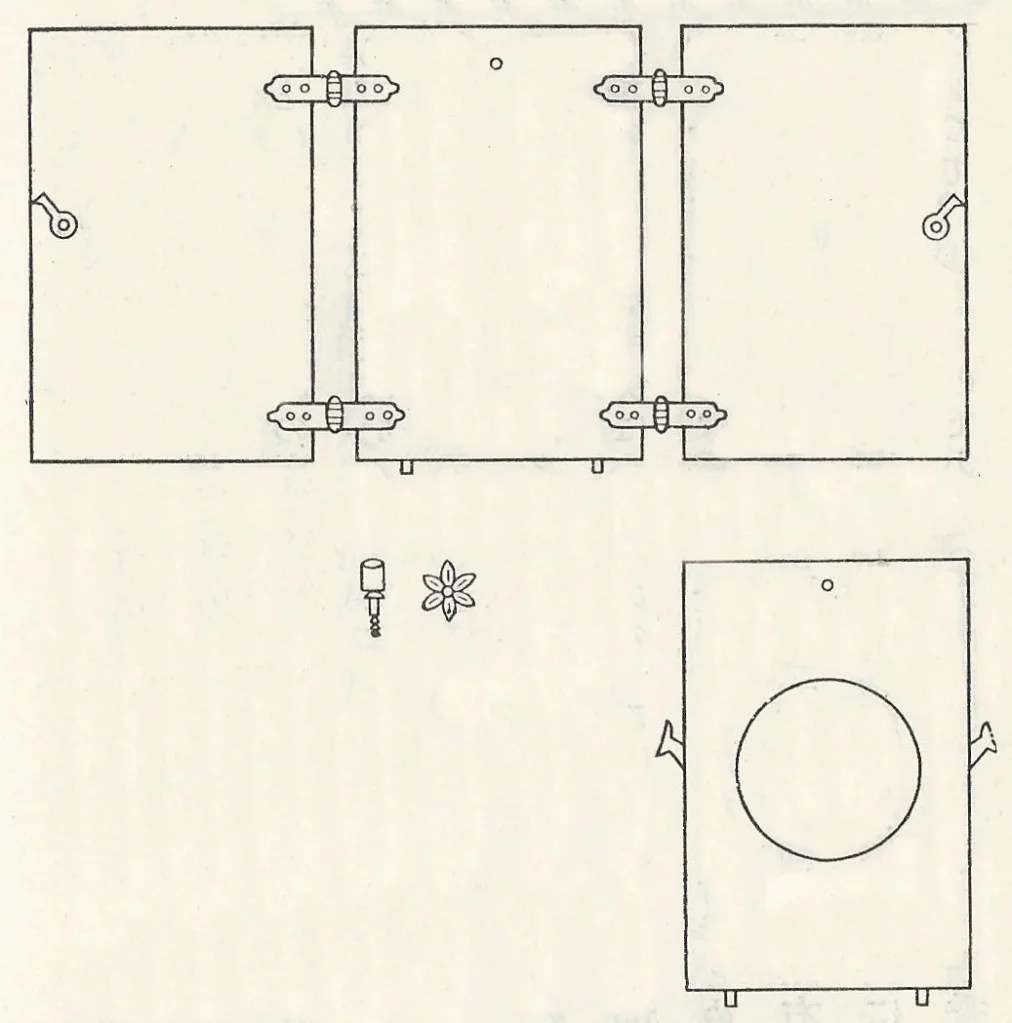

Unlike European Lantern Clocks, the Japanese tokei-shi came up with a unique arrangement for fitting side and rear panels. Their construction method hinged the three plates together as a single unit. The rear panel was located by securing the lower edge with a pair of lugs into the baseplate, and the upper section was then secured with a thumbscrew through the plate into the rear frame upright. The side plates then hinged closed and secured by a simple hook catch each side. This facility enabled quick and easy access to the whole mechanism.

Typical Manufacturing Process of a Wadokei

During the Koka era (1844-1848) Lord Junsho of Tsugaru Castle ordered KOKONOE Fujikichi to make a Wadokei. KOKONOE’s estimate that extended to a ten page book survives. Details of the estimate were detailed in Taizaburo Tsukada’s book of 1960 called “Wadokei”. Below is a summary of the fascinating estimate that not only provides details of all the component parts, but raw materials and the man days of effort to make each component part, fit them, and to inspect them and make operational. Below is a summary extract from the estimate.

Raw Materials with detailed amounts

- Iron Ore

- Steel from Iron

- Forging Charcoal

- Smiths Daily Wages

- Daily Workers’ Wages

- Crimson Hood of Gold Bronze

- Borax

- Charcoal

- Lead

Finished Materials with detailed amounts

- Four tyoes of Rubbing Stones

- Varnish (yoshino-urushi)

- Undercoating Varnish

- Bleached Cotton Cloth

- Best Mino-Paper

- Best Japanese Paper

- Varnish Brush

- Best Gold Powders

- Floss

From the Pharmacy with detailed amounts

- Glossary Cloth

- Camelia Oil

- Lacquering Brush

- Hair Brisle Brush

From the Leather Shop with detailed amounts

- White Deerskin

- Cowhide

For Shrine Employees

- 30 Candles each

Listing of 42 Component Parts, typically:

- Rear (Strike) First Wheel – 120 man days

- Rear (Strike) First Arbor – 55 man days

- Count Wheel – 55 man days

- Balance Foliot – 55 man days

- Front Hand – 15 man days

- Center Post – 55 man days

- Each man day was charged in a weight of silver equal to approximately 24 gramme

Listing of Labour to Fit all the Components

- 121 man days

Typical Lantern Wadokei with Typical Times to Make / Fit Components